Low-vibration, low-noise, power-saving facility with the world's first 3-stage continuously variable pitch screw

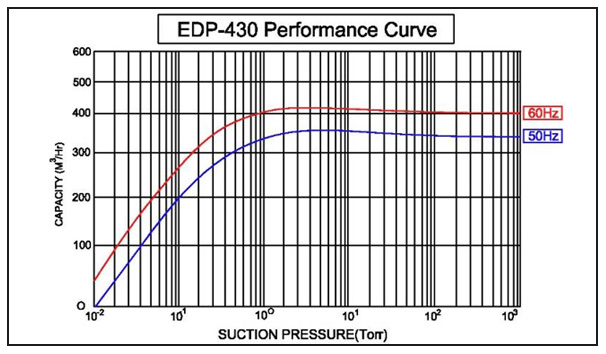

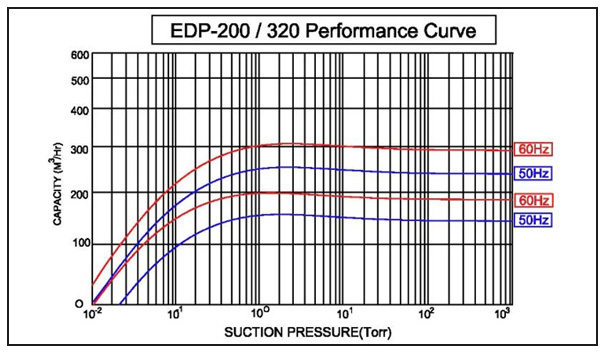

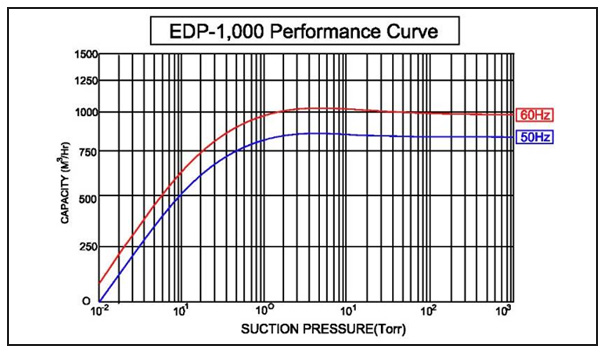

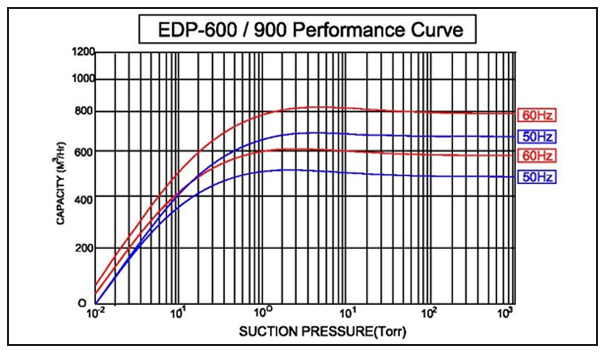

Capacity : 130 ㎥/hr ~ 1000 ㎥/hr (50/60Hz)

Vacuum level: 1×10-2 Torr

Characteristic:

3-stage continuous variable pitch type screw adoption

Inhalation efficiency ↑, Vacuum ↑, Power consumption 34% ↓, Exhaust temperature 50% ↓

Simple structural design method

Easy maintenance/repair, Reduced management costs (30 ~ 40%).

Apply various coatings to the right place (PFA, PEEK, Nickel, Hastelloy Coating)

Apply PEEK and Teflon coating to the gas contact area.

Maintaining excellent corrosion resistance and wear resistance.

Not using mechanical seals.

No residual failure due to seal wear and contamination, and bearing durability is maintained.

Using IEC Flange Motor.

Easy to install and less noise and vibration.