Customized vacuum pump/System design. Production, Installation, Commissioning, Service.

Production considering Stable operation, High efficiency, Energy saving, and User convenience

System design optimized for process and utility conditions

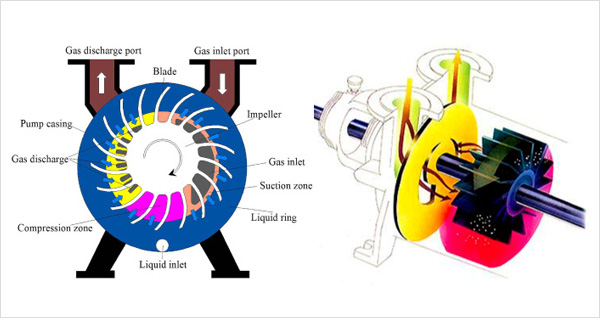

Principle :

Liquidated vacuum pumps are used in a variety of applications.

This pump is a volumetric pump, and an impeller is eccentrically installed in the housing to create a vacuum.

It mainly uses water, and when the impeller rotates, the liquid forms sealing in the casing, and gas is transferred to the space between the blade and the liquid.

Gas is delivered to the center and to the space between each blade and the liquid bar, and the impeller is eccentrically arranged, increasing the volume of the inlet and suctioning the gas through the inlet.

As the impeller continues to rotate, the volume of the outlet decreases, and the gas compresses and exits through the outlet.

The oil-repellent vacuum pump can be operated with a One-though system, a full recirculation, or some recirculation system. The vacuum pump operates generally on the same temperature line as the fluid inside the vacuum pump cylinder continues to lower the compression heat.This means that the process gas is not noticeably heated and the vacuum pump operates at a relatively low temperature.

As a result, the risk of unintended reactions or explosions is greatly reduced. In addition, the operating temperature is low, allowing condensation of water vapor and gas, which leads to an increase in the pump capacity of the vacuum pump.

Characteristic :

· Suitable for gas exhaust containing water vapor or moisture.

· Excellent for exhausting combustible and corrosive gases.

· Quiet driving is possible due to low noise and vibration.

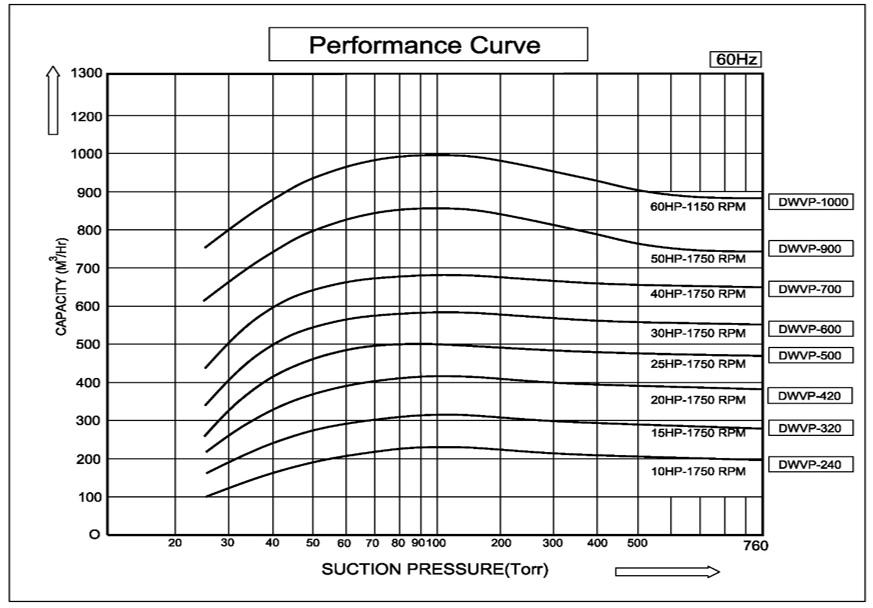

· High exhaust efficiency at low pressure of 200 Torr as a 2-stage

· No pulsation at all in the continuous exhaust method.

· No risk of failure because there is no friction between Impellar and Casing

· Efficiency and maximum vacuum have improved more than conventional NASH types.

· Easy to select materials according to the process.